How AI is Revolutionizing G-Code Generation for CNC Machines

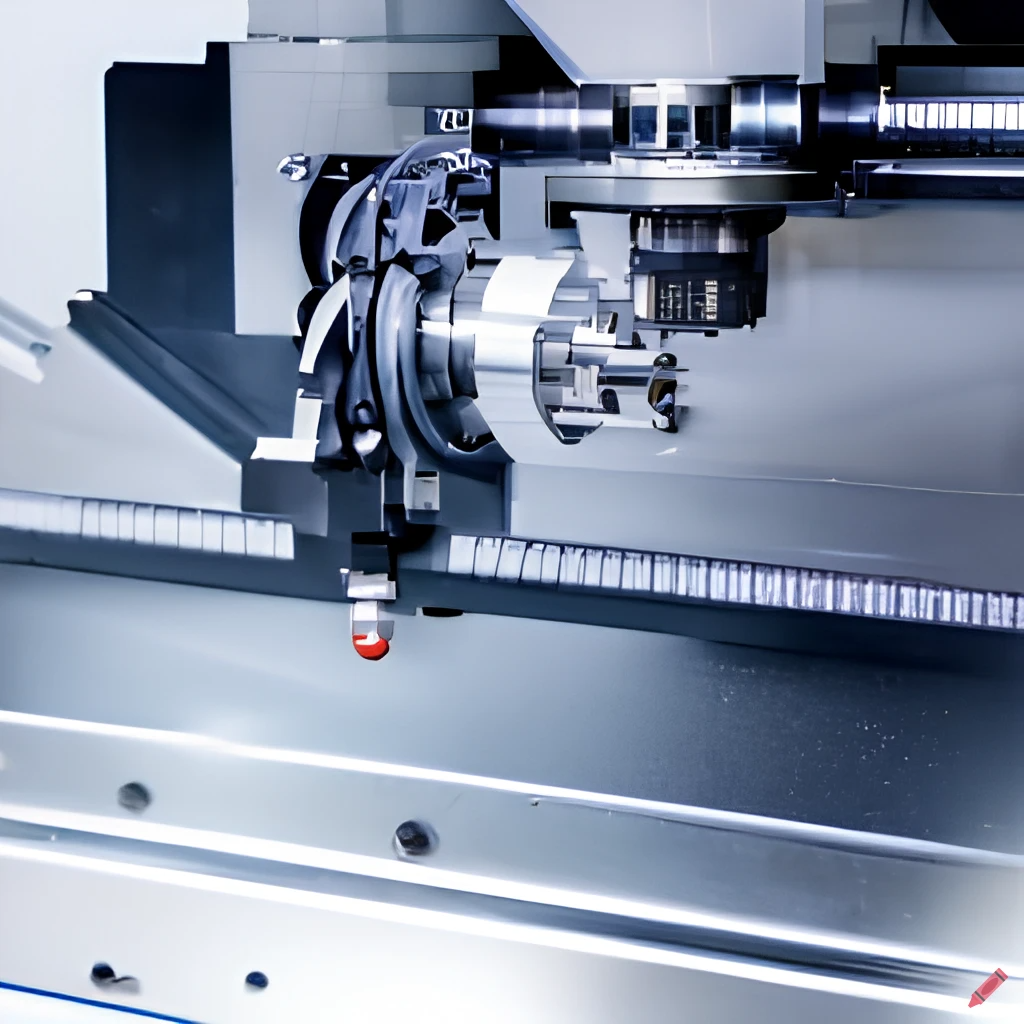

G-code has been the standard programming language used for CNC machines for decades. However, with advancements in Artificial Intelligence (AI) and machine learning, it is now possible to generate G-code using AI algorithms. This technology is revolutionizing the manufacturing industry, making it easier and faster to produce complex parts with high precision and accuracy.

Traditionally, creating G-code programs requires skilled programmers who have expertise in programming languages and a deep understanding of the manufacturing process. However, AI can now generate G-code programs automatically, based on inputs from the user, such as the dimensions and shape of the part, the type of material being used, and the desired level of precision.

AI algorithms work by analyzing vast amounts of data and identifying patterns and trends. They use this information to create optimized G-code programs that minimize the amount of material waste, reduce machining time, and ensure high accuracy and precision.

One of the key advantages of using AI for G-code generation is its ability to optimize the machining process based on real-time data. For example, if a tool breaks or wears out during the machining process, the AI algorithm can automatically adjust the G-code program to compensate for the change. This helps to minimize downtime and ensures that the machining process is always optimized for maximum efficiency.

Another benefit of using AI for G-code generation is that it can help to reduce errors and inconsistencies in the machining process. Because the AI algorithm is programmed to follow a set of rules and parameters, it can ensure that the final product is consistent and meets the required specifications.

To illustrate how AI can generate G-code programs, let’s consider the example of a simple shaft that we programmed earlier. Using an AI algorithm, we can input the dimensions of the raw material and the desired shape of the part. The AI algorithm will then analyze this information and create an optimized G-code program that will produce the part with maximum efficiency and accuracy.

The use of AI for G-code generation is still relatively new, and there are some challenges that need to be addressed. For example, the algorithms need to be trained on large datasets to ensure that they can accurately predict the best G-code program for a given task. Additionally, there is a need for skilled technicians who can oversee the AI algorithms and ensure that they are producing high-quality parts.

In conclusion, the use of AI for G-code generation is transforming the manufacturing industry, making it easier and faster to produce complex parts with high precision and accuracy. As this technology continues to evolve, we can expect to see even more advanced AI algorithms that can optimize the machining process in real-time, further reducing errors and increasing efficiency.

Everyone loves what you guys are usually up too. Such clever work and reporting!

Keep up the superb works guys I’ve included you guys to my own blogroll.

Excellent post. I was checking continuously this weblog and I am inspired!

Extremely useful info specifically the last part :

) I take care of such information much. I

used to be seeking this certain info for a

very lengthy time. Thanks and good luck.

Simply wanna input that you have a very nice website , I like the design and style it actually stands out.

Nice post. I was checking continuously this blog and I’m impressed!

Extremely useful info particularly the last part

🙂 I care for such info a lot. I was seeking this certain information for a long time.

Thank you and good luck.

Very interesting topic, thankyou for putting up.

It’s really a nice and useful piece of info. I am satisfied that you shared this helpful info with us.

Please stay us informed like this. Thank you for sharing.

Hey there! I could have sworn I’ve been to this site before but after checking through some of the post I realized it’s new to me. Nonetheless, I’m definitely happy I found it and I’ll be bookmarking and checking back frequently!

Hey, you used to write excellent, but the last few posts have been kinda boring?K I miss your great writings. Past several posts are just a little bit out of track! come on!

Really Appreciate this blog post, is there any way I can get an alert email when you publish a fresh article?

This really answered my downside, thanks!

I will right away grab your rss feed as I can’t find your e-mail subscription link or e-newsletter service. Do you have any? Kindly let me know in order that I could subscribe. Thanks.

I am impressed with this web site, real I am a fan.

It’s hard to find knowledgeable people on this topic, but you sound like you know what you’re talking about! Thanks

I couldn’t resist commenting

Very interesting topic, thanks for posting.

PrimeBiome is a premium probiotic formula that focuses on restoring the natural balance of good bacteria in the gut. By doing so, it helps reduce digestive discomfort, supports immune function, and boosts nutrient absorption.

ProstaVive is a dietary supplement formulated specifically for men dealing with prostate-related problems. It uses a science-backed blend of herbal extracts, vitamins, and minerals to target inflammation, support normal prostate size, and improve urinary control.

Really clean website , thanks for this post.

Woah! I’m really loving the template/theme of this website. It’s simple, yet effective. A lot of times it’s tough to get that “perfect balance” between superb usability and visual appearance. I must say you have done a fantastic job with this. Also, the blog loads very quick for me on Safari. Superb Blog!

I truly prize your work, Great post.

We are a group of volunteers and opening a new scheme in our community. Your website provided us with valuable info to work on. You’ve done an impressive job and our entire community will be grateful to you.

Everything is very open and very clear explanation of issues. was truly information. Your website is very useful. Thanks for sharing.

Great post. I was checking constantly this blog and

I’m inspired! Extremely useful information specially the last

phase 🙂 I deal with such information a lot. I used to be

seeking this certain info for a very long time. Thanks and best of luck.

Hmm is anyone else having problems with the images on this blog loading? I’m trying to figure out if its a problem on my end or if it’s the blog. Any feedback would be greatly appreciated.

Greetings! I know this is kinda off topic but I was wondering which blog platform are you using for this site? I’m getting tired of WordPress because I’ve had issues with hackers and I’m looking at options for another platform. I would be fantastic if you could point me in the direction of a good platform.

As soon as I observed this website I went on reddit to share some of the love with them.

Loving the information on this site, you have done great job on the articles.

This really answered my downside, thanks!

Appreciating the hard work you put into your website and in depth information you provide. It’s nice to come across a blog every once in a while that isn’t the same unwanted rehashed information. Great read! I’ve saved your site and I’m including your RSS feeds to my Google account.

Just what I was looking for, regards for putting up.

I found your blog site on google and examine just a few of your early posts. Continue to maintain up the very good operate. I just additional up your RSS feed to my MSN Information Reader. Seeking forward to reading more from you later on!…

It’s best to take part in a contest for top-of-the-line blogs on the web. I’ll suggest this site!

I have been checking out many of your stories and it’s pretty clever stuff. I will make sure to bookmark your blog.

I believe you have remarked some very interesting details, appreciate it for the post.

F*ckin’ awesome things here. I am very glad to look your post. Thank you a lot and i am looking ahead to touch you. Will you kindly drop me a e-mail?

You really make it seem so easy along with your presentation but I to find this matter to be really one thing which I believe I would never understand. It sort of feels too complicated and extremely vast for me. I am having a look ahead on your next put up, I?¦ll attempt to get the cling of it!

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Hi, i believe that i saw you visited my website thus i came to “go back the prefer”.I’m attempting to to find issues to enhance my web site!I suppose its ok to use some of your concepts!!

Great write-up, I am regular visitor of one’s blog, maintain up the excellent operate, and It is going to be a regular visitor for a lengthy time.

Great write-up, I am normal visitor of one’s web site, maintain up the excellent operate, and It’s going to be a regular visitor for a long time.

Excellent post! We are linking to this particularly great article on our website.

Keep up the great writing.

Excellent website. Plenty of useful info here. I’m sending it to some

buddies ans additionally sharing in delicious.

And of course, thanks on your sweat!

When I originally left a comment I seem to have clicked the -Notify me when new comments are added- checkbox

and from now on whenever a comment is added I recieve 4 emails with the exact same

comment. There has to be a way you are able to remove me from that service?

Appreciate it!

Thanks for helping out, wonderful information.

Excellent post. I was checking continuously this blog and I am impressed! Extremely useful info specially the last part 🙂 I care for such information a lot. I was seeking this certain information for a very long time. Thank you and best of luck.

F*ckin¦ amazing things here. I am very happy to see your article. Thank you so much and i am having a look forward to touch you. Will you kindly drop me a mail?

I will immediately clutch your rss as I can not in finding your e-mail subscription link or e-newsletter service. Do you have any? Please permit me recognise so that I could subscribe. Thanks.

I visited several web sites but the audio feature for audio songs existing at this website is really

marvelous.

Personally I trust Temanslot more than other sites

It’s awesome for me to have a web site, which is good in favor of my knowledge.

thanks admin

When I initially commented I clicked the -Notify me when new comments are added- checkbox and now each time a remark is added I get four emails with the same comment. Is there any approach you may take away me from that service? Thanks!

Situs Slot Kaptenasia

Hey there! I know this is kinda off topic but I was wondering which blog platform are you using for this site? I’m getting tired of WordPress because I’ve had problems with hackers and I’m looking at options for another platform. I would be fantastic if you could point me in the direction of a good platform.

Thank you for another informative blog. The place else may I get that type of info written in such a perfect means? I’ve a undertaking that I am just now operating on, and I have been on the glance out for such information.

If some one wishes to be updated with most recent technologies

therefore he must be pay a quick visit this website and be up to date everyday.

I just could not depart your site before suggesting that I actually enjoyed the standard information a person provide for your visitors? Is gonna be back often in order to check up on new posts

Thanks for helping out, good info. “If at first you don’t succeed, find out if the loser gets anything.” by Bill Lyon.

As soon as I noticed this site I went on reddit to share some of the love with them.

I just could not depart your website prior to suggesting that I extremely enjoyed the standard information a person provide for your visitors? Is going to be back often in order to check up on new posts

Your article helped me a lot, is there any more related content? Thanks!

fantastic publish, very informative. I wonder why the opposite experts of this sector don’t realize this.

You must proceed your writing. I’m sure, you’ve a

huge readers’ base already!

It’s very effortless to find out any topic on web as compared to textbooks, as I found this piece of writing at this website.

Appreciate the recommendation. Let me try it out.

Woah! I’m really digging the template/theme of this site.

It’s simple, yet effective. A lot of times it’s challenging to get that “perfect balance” between user

friendliness and visual appeal. I must say you’ve done a excellent job with this.

Additionally, the blog loads super quick for me

on Firefox. Superb Blog!

Awsome article and straight to the point. I don’t know if this is really the best place to ask but do you folks have any ideea where to employ some professional writers? Thanks 🙂

I think you have mentioned some very interesting details, regards for the post.

Sweet site, super layout, rattling clean and apply pleasant.

each time i used to read smaller posts that also clear their motive, and that

is also happening with this article which I am reading here.

Regards for helping out, excellent info. “If at first you don’t succeed, find out if the loser gets anything.” by Bill Lyon.

Incredible points. Sound arguments. Keep up the amazing work.

I really enjoy reading through on this site, it has got superb blog posts.

I’ll immediately grab your rss feed as I can not find your email subscription link or newsletter service. Do you have any? Please let me know in order that I could subscribe. Thanks.

Great blog! I am loving it!! Will be back later to read some more. I am taking your feeds also

Arialief is a cutting-edge, plant-based formula specifically designed to tackle the root causes of pain rather than just masking the symptoms.

Thank you a lot for sharing this with all

of us you really know what you’re talking approximately!

Bookmarked.Please also seek advice from my site =).

We could have a link exchange agreement between us

I really love your blog.. Excellent colors & theme. Did you create this website

yourself? Please reply back as I’m attempting to create my own personal site and would like to know where you got this from or exactly what the theme is named.

Many thanks!

Ahaa, its pleasant conversation regarding this paragraph here at this weblog, I have read all that, so now me also commenting at

this place.

Excellent site. Lots of useful info here. I am sending it to a few friends ans also sharing in delicious. And certainly, thanks for your effort!

Great postings. Many thanks.

It’s impressive that you are getting ideas from this piece of writing as well as from our discussion made at this time.

Its great as your other blog posts : D, regards for putting up.

Very nice article. I absolutely love this site. Continue the good

work!

It’s actually a cool and useful piece of info.

I’m satisfied that you simply shared this useful info with us.

Please stay us up to date like this. Thank you for sharing.

I like this web blog its a master peace ! Glad I found this on google .

Hi there, of course this post is genuinely fastidious and I have learned lot of things from it about blogging.

thanks.

I like what you guys are up also. Such intelligent work and reporting! Carry on the superb works guys I’ve incorporated you guys to my blogroll. I think it will improve the value of my website :).

Good info. Lucky me I reach on your website by accident, I bookmarked it.

When I originally commented I clicked the “Notify me when new comments are added” checkbox and now each time a

comment is added I get four e-mails with the same comment.

Is there any way you can remove people from that service?

Cheers!

Truly tons of superb info!

I am in fact glad to read this blog posts which includes tons of valuable data, thanks for

providing such information.

Some genuinely nice stuff on this website , I enjoy it.

Do you mind if I quote a couple of your posts as long as I provide credit and sources back to your website? My website is in the exact same niche as yours and my visitors would truly benefit from some of the information you provide here. Please let me know if this alright with you. Thanks!

It is really a great and helpful piece of information. I’m glad that you shared this helpful info with us. Please keep us informed like this. Thank you for sharing.

If some one desires to be updated with most recent technologies then he must

be visit this web page and be up to date all

the time.

Way cool! Some very valid points! I appreciate you writing this article plus the rest of the site is also very good.

Link exchange is nothing else except it is simply placing the other person’s webpage link

on your page at proper place and other person will

also do similar in support of you.

As soon as I discovered this internet site I went on reddit to share some of the love with them.

F*ckin’ awesome things here. I am very glad to see your post. Thanks a lot and i’m looking forward to contact you. Will you please drop me a e-mail?

I conceive this website has some rattling good info for everyone : D.

Woah! I’m really loving the template/theme of this blog.

It’s simple, yet effective. A lot of times it’s very hard

to get that “perfect balance” between superb usability and visual appeal.

I must say you have done a amazing job with this. Also, the blog loads super fast for me

on Opera. Superb Blog!

I am often to blogging and i really appreciate your content. The article has really peaks my interest. I am going to bookmark your site and keep checking for new information.

Hiya very nice website!! Man .. Excellent .. Wonderful .. I’ll bookmark your site and take the feeds additionally?KI’m satisfied to seek out so many helpful info right here within the submit, we need develop more techniques in this regard, thanks for sharing. . . . . .

Do you mind if I quote a couple of your posts as long as I provide credit and sources back to your blog? My blog site is in the very same area of interest as yours and my visitors would truly benefit from a lot of the information you provide here. Please let me know if this alright with you. Thank you!

It’s actually a nice and helpful piece of information. I’m glad that you shared this helpful information with us. Please keep us up to date like this. Thanks for sharing.

Ich bin nicht positiv der Ort Sie sind erhalten Ihre Informationen, aber gut Thema. Ich muss eine Weile damit verbringen, mehr zu lernen oder mehr herauszufinden. Danke für die großartige Info war auf der Suche nach diesem Info für meine Mission.

Really fantastic visual appeal on this site, I’d value it 10 10.

As a Newbie, I am permanently browsing online for articles that can benefit me. Thank you

Very interesting points you have mentioned, thanks for putting up. “I’ve made a couple of mistakes I’d like to do over.” by Jerry Coleman.

This website is my intake, very excellent style and design and perfect subject matter.

I’m still learning from you, while I’m improving myself. I certainly love reading all that is posted on your blog.Keep the stories coming. I liked it!

Very interesting points you have observed, thankyou for posting. “The only thing worse than a man you can’t control is a man you can.” by Margo Kaufman.

Nearly all of whatever you mention happens to be astonishingly precise and that makes me wonder why I had not looked at this in this light previously. Your piece truly did turn the light on for me as far as this specific issue goes. Nevertheless there is just one point I am not really too comfy with so while I make an effort to reconcile that with the main theme of the point, permit me observe just what the rest of the subscribers have to say.Very well done.

Great post. I was checking constantly this blog and I am impressed! Very helpful information specifically the last part 🙂 I care for such information much. I was seeking this certain information for a long time. Thank you and good luck.

Regards for this post, I am a big big fan of this site would like to go along updated.

Woh I like your content, saved to bookmarks! .

I used to be suggested this website through my cousin. I’m no longer sure whether

this put up is written via him as no one else realize such distinct about my difficulty.

You’re wonderful! Thanks!

I simply couldn’t go away your website before suggesting that I actually enjoyed the standard information an individual supply

on your guests? Is going to be back regularly to investigate cross-check

new posts

Fine way of telling, and good piece of writing to

take data on the topic of my presentation subject, which i am going

to convey in college.

I like what you guys are up also. Such smart work and reporting! Keep up the excellent works guys I’ve incorporated you guys to my blogroll. I think it will improve the value of my website 🙂

Great post, you have pointed out some great details , I as well believe this s a very excellent website.

Very good info. Lucky me I came across your website by

chance (stumbleupon). I have bookmarked it for later!

Hey very nice site!! Man .. Excellent .. Wonderful .. I’ll bookmark your blog and take the feeds also…I’m glad to search out numerous helpful info here within the post, we need develop extra strategies on this regard, thanks for sharing.

When I initially commented I clicked the -Notify me when new feedback are added- checkbox and now every time a remark is added I get 4 emails with the identical comment. Is there any means you can take away me from that service? Thanks!

I am glad to be one of many visitors on this outstanding web site (:, thanks for putting up.

What’s up to all, because I am truly keen of reading this website’s post to be updated

daily. It includes pleasant data.

After all, what a great site and informative posts, I will upload inbound link – bookmark this web site? Regards, Reader.

you have a great blog here! would you like to make some invite posts on my blog?

great post.Never knew this, appreciate it for letting me know.

Great write-up, I?¦m normal visitor of one?¦s site, maintain up the excellent operate, and It’s going to be a regular visitor for a long time.

Very interesting information!Perfect just what I was looking for!

I love your writing style genuinely enjoying this internet site.

Very interesting subject , appreciate it for putting up.

Paragraph writing is also a fun, if you know then you can write otherwise it is difficult to write.

k8bth7

This site is my inhalation, real superb pattern and perfect written content.

Well I really liked studying it. This post procured by you is very effective for correct planning.

You made certain good points there. I did a search on the subject and found most people will consent with your blog.

so much excellent info on here, : D.

Enjoyed reading through this, very good stuff, regards.

After study a few of the blog posts on your website now, and I truly like your way of blogging. I bookmarked it to my bookmark website list and will be checking back soon. Pls check out my web site as well and let me know what you think.

I like what you guys are up also. Such smart work and reporting! Keep up the excellent works guys I?¦ve incorporated you guys to my blogroll. I think it’ll improve the value of my web site 🙂

Excellent post. I was checking constantly this blog and I’m impressed! Extremely useful information specifically the last part 🙂 I care for such information a lot. I was looking for this particular info for a long time. Thank you and good luck.

Some really good articles on this website, regards for contribution. “Be absolutely determined to enjoy what you do.” by Sarah Knowles Bolton.

I visited several sites but the audio quality for audio songs existing at this web site is genuinely excellent.

I’m really enjoying the theme/design of your web site. Do you ever run into any web browser compatibility problems? A couple of my blog readers have complained about my website not working correctly in Explorer but looks great in Safari. Do you have any suggestions to help fix this issue?

Normally I don’t read article on blogs, but I wish to say that this write-up very compelled me to take a look at and do it! Your writing style has been amazed me. Thanks, quite nice article.

You have mentioned very interesting points! ps decent web site.

I am constantly browsing online for posts that can benefit me. Thx!

I am not sure where you’re getting your info, but good topic. I needs to spend some time learning much more or understanding more. Thanks for great information I was looking for this info for my mission.

Cool blog! Is your theme custom made or did you download it from somewhere? A theme like yours with a few simple tweeks would really make my blog shine. Please let me know where you got your theme. Many thanks

Hi, I think your site might be having browser compatibility issues. When I look at your website in Safari, it looks fine but when opening in Internet Explorer, it has some overlapping. I just wanted to give you a quick heads up! Other then that, fantastic blog!

An intriguing discussion is worth comment. I do believe that you ought to publish more about this subject,

it may not be a taboo subject but typically folks don’t speak about

these topics. To the next! Kind regards!!

I’m still learning from you, but I’m trying to reach my goals. I definitely liked reading all that is posted on your blog.Keep the stories coming. I enjoyed it!

These are truly impressive ideas in regarding blogging. You have touched some pleasant factors here.

Any way keep up wrinting.

Would love to always get updated great site! .

Remarkable! Its genuinely remarkable piece of writing, I have got much clear idea regarding

from this piece of writing.

Its wonderful as your other posts : D, thanks for posting.

Your article helped me a lot, is there any more related content? Thanks!

Interesting blog! Is your theme custom made or did you download it from somewhere?

A theme like yours with a few simple adjustements would really make my blog stand

out. Please let me know where you got your design. Bless you

A fascinating discussion is definitely worth comment. I think that

you ought to publish more about this subject, it might not

be a taboo matter but usually people don’t talk about such topics.

To the next! Best wishes!!

Superb, what a weblog it is! This weblog gives helpful facts to us, keep

it up.

Sweet internet site, super layout, real clean and use friendly.

Great info. Lucky me I recently found your site by chance (stumbleupon).

I have bookmarked it for later!

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

When I initially commented I clicked the “Notify me when new comments are added” checkbox and now

each time a comment is added I get four e-mails

with the same comment. Is there any way you can remove me from that service?

Cheers!

I like reading a post that can make people think. Also,

thank you for allowing me to comment!

Greetings! Very helpful advice in this particular post!

It’s the little changes that will make the greatest changes.

Thanks a lot for sharing!

Definitely imagine that which you stated. Your favourite reason seemed

to be on the web the simplest factor to take into account of.

I say to you, I definitely get irked while other folks think about concerns

that they plainly don’t understand about. You managed to hit the nail upon the top as neatly

as outlined out the entire thing with no need side effect , other people could take a signal.

Will probably be back to get more. Thanks

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

Hey very nice blog!

Hey very nice site!! Man .. Beautiful .. Amazing .. I will bookmark your web site and take the feeds also…I’m happy to find numerous useful information here in the post, we need develop more strategies in this regard, thanks for sharing. . . . . .

Your article helped me a lot, is there any more related content? Thanks!

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Hi my friend! I want to say that this post is awesome, nice written and include almost all significant infos. I would like to see more posts like this.

Do you mind if I quote a few of your articles as long as I

provide credit and sources back to your weblog? My blog is in the very same area of interest as yours and my visitors

would genuinely benefit from a lot of the information you present here.

Please let me know if this alright with you. Many thanks!

Pretty! This has been an extremely wonderful article.

Thank you for supplying these details.

Hey very cool site!! Man .. Excellent .. Amazing .. I will bookmark your site and take the feeds also…I am happy to find a lot of useful info here in the post, we need work out more strategies in this regard, thanks for sharing. . . . . .

I always emailed this website post page to all my friends,

because if like to read it then my links will too.

Simply wanna remark that you have a very nice website , I love the design and style it really stands out.

Just what I was looking for, thanks for posting.

Hey very cool web site!! Man .. Excellent .. Amazing .. I’ll bookmark your website and take the feeds also…I’m happy to find so many useful info here in the post, we need develop more techniques in this regard, thanks for sharing. . . . . .

The Natural Mounjaro Recipe is more than just a diet—it’s a sustainable and natural approach to weight management and overall health.

I went over this internet site and I think you have a lot of excellent information, bookmarked (:.

I just like the helpful information you supply for your articles. I will bookmark your blog and test once more here regularly. I am rather sure I’ll learn plenty of new stuff right here! Best of luck for the following!

This is my first time pay a visit at here

and i am really impressed to read everthing

at single place.

As a Newbie, I am constantly browsing online for articles that can help me. Thank you

Really wonderful visual appeal on this internet site, I’d value it 10 10.

Highly energetic article, I liked that a lot.

Will there be a part 2?

Wonderful website. Lots of helpful information here. I am sending it to some buddies ans also sharing in delicious. And obviously, thanks in your effort!

I like the efforts you have put in this, thanks for all the great articles.

Your article helped me a lot, is there any more related content? Thanks!

There is definately a great deal to know

about this issue. I love all of the points you’ve made.

Enjoyed reading through this, very good stuff, appreciate it. “It requires more courage to suffer than to die.” by Napoleon Bonaparte.

Pretty! This was a really wonderful post. Thank you for your provided information.

Nerve Calm is an advanced nerve support formula that combines a synergistic blend of essential vitamins, minerals, and herbal extracts.

Simply want to say your article is as astonishing. The clearness to your submit is just nice and that i can think you are a professional in this subject. Fine along with your permission let me to grasp your feed to stay up to date with impending post. Thanks a million and please continue the gratifying work.

It is in point of fact a nice and helpful piece of information. I am satisfied that you just shared this useful info with us. Please keep us informed like this. Thank you for sharing.

I really like your writing style, excellent information, thanks for putting up : D.

Hmm is anyone else experiencing problems with the images on this blog loading? I’m trying to determine if its a problem on my end or if it’s the blog. Any responses would be greatly appreciated.

Prime Biome is a cutting-edge probiotic and gut health supplement designed to support digestive wellness, boost immunity, and enhance overall vitality.

Good write-up, I¦m regular visitor of one¦s web site, maintain up the nice operate, and It’s going to be a regular visitor for a long time.

Mitolyn is a cutting-edge natural dietary supplement designed to support effective weight loss and improve overall wellness.

Enjoyed reading through this, very good stuff, regards. “Success doesn’t come to you…you go to it.” by Marva Collins.

Hmm is anyone else experiencing problems with

the pictures on this blog loading? I’m trying to figure out if its a problem on my end

or if it’s the blog. Any responses would be greatly appreciated.

Merely wanna tell that this is invaluable, Thanks for taking your time to write this.

Some really interesting info , well written and broadly speaking user genial.

Great website! I am loving it!! Will be back later to read some more. I am bookmarking your feeds also.

Absolutely indited written content, regards for entropy.

Hi there! This post couldn’t be written any better! Reading through this post reminds me of my previous room mate! He always kept talking about this. I will forward this article to him. Pretty sure he will have a good read. Thank you for sharing!

Appreciate this post. Will try it out.

to access this world language learning link is very easy

very nice publish, i definitely love this website, keep on it

Perfect piece of work you have done, this web site is really cool with excellent information.

This site is very educational in providing important lessons and insights.

Hiya, I am really glad I have found this information. Today bloggers publish only about gossips and internet and this is actually irritating. A good site with interesting content, that’s what I need. Thank you for keeping this site, I will be visiting it. Do you do newsletters? Can’t find it.

I have been reading out some of your stories and i can claim pretty nice stuff. I will definitely bookmark your site.

Hi mates, its enormous paragraph regarding educationand fully explained, keep it

up all the time.

It’s an awesome post in support of all the online people; they will take benefit from it I am sure.

Amazing all kinds of superb information!

I love your writing style truly enjoying this site.

I wanted to thank you for this great read!! I definitely enjoying every little bit of it I have you bookmarked to check out new stuff you post…

The Natural Mounjaro Recipe is more than just a diet—it’s a sustainable and natural approach to weight management and overall health.

The Natural Mounjaro Recipe is more than just a diet—it’s a sustainable and natural approach to weight management and overall health.

Mitolyn is a cutting-edge natural dietary supplement designed to support effective weight loss and improve overall wellness.

I’d perpetually want to be update on new blog posts on this web site, bookmarked! .

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

ProstaVive is a premium, plant-based dietary supplement specifically formulated to support prostate health, reduce inflammation, and enhance urinary function, especially for men over the age of 40.

Great write-up, I am regular visitor of one’s site, maintain up the nice operate, and It’s going to be a regular visitor for a long time.

Marvelous, what a weblog it is! This blog provides helpful facts

to us, keep it up.

You have brought up a very wonderful points, appreciate it for the post.

After study a few of the blog posts on your website now, and I truly like your way of blogging. I bookmarked it to my bookmark website list and will be checking back soon. Pls check out my web site as well and let me know what you think.

This web site is my intake, very fantastic design and perfect subject material.

I like this web blog so much, saved to my bookmarks.

You made the point!

I don’t normally comment but I gotta tell regards for the post on this amazing one : D.

E2Bet Indonesia, situs judi online terbesar

di Indonesia, aman, terpercaya, dan inovatif, bonus menarik dan layanan pelanggan 24/7.

#E2Bet #E2BetIndonesia #Indonesia

Your article helped me a lot, is there any more related content? Thanks!

I think this site has got some real excellent info for everyone : D.

I’m not sure why but this blog is loading very slow for me.

Is anyone else having this problem or is it a problem

on my end? I’ll check back later and see if the problem still exists.

I like this blog very much, Its a rattling nice berth to read and incur info .

Hi, i think that i saw you visited my site thus i got here to “go back the want”.I am attempting to to find issues to improve my site!I suppose its adequate to use some of your concepts!!

I like what you guys are up also. Such smart work and reporting! Keep up the excellent works guys I?¦ve incorporated you guys to my blogroll. I think it will improve the value of my web site 🙂

The Natural Mounjaro Recipe is more than just a diet—it’s a sustainable and natural approach to weight management and overall health.

F*ckin’ amazing things here. I am very glad to see your article. Thanks a lot and i’m looking forward to contact you. Will you kindly drop me a e-mail?

I like this web blog very much, Its a really nice place to read and find info .

Hi, Neat post. There’s a problem together with your site in web explorer, might check this… IE still is the market chief and a big part of other folks will omit your fantastic writing because of this problem.

I like your writing style really loving this site.

I just like the helpful information you provide on your articles. I’ll bookmark your weblog and test once more right here regularly. I’m quite sure I will be informed plenty of new stuff proper here! Best of luck for the next!

Exactly what I was looking for, thanks for posting.

Your article helped me a lot, is there any more related content? Thanks!

You made some decent points there. I did a search on the subject matter and found most people will agree with your blog.

Glad to be one of the visitants on this awe inspiring website : D.

excellent post, very informative. I wonder why the other specialists of this sector don’t notice this. You must continue your writing. I am confident, you have a great readers’ base already!

Simply wanna remark on few general things, The website style and design is perfect, the articles is rattling good. “The idea of God is the sole wrong for which I cannot forgive mankind.” by Marquis de Sade.

Hi, Neat post. There’s an issue together with your website in web explorer, would check this… IE nonetheless is the market chief and a large section of other people will leave out your wonderful writing due to this problem.

I’d always want to be update on new articles on this web site, saved to my bookmarks! .

I simply could not leave your website before suggesting that I really loved the usual info an individual provide in your visitors? Is going to be back steadily in order to investigate cross-check new posts.

you are actually a just right webmaster. The web site loading velocity is incredible. It kind of feels that you are doing any unique trick. Furthermore, The contents are masterpiece. you’ve done a magnificent process on this matter!

As I website possessor I think the subject matter here is real fantastic, appreciate it for your efforts.

I carry on listening to the news bulletin speak about receiving boundless online grant applications so I have been looking around for the finest site to get one. Could you advise me please, where could i acquire some?

Way cool! Some very valid points! I appreciate you writing this write-up plus the rest

of the site is really good.

Does your blog have a contact page? I’m having a tough time locating it but, I’d like to send you an email. I’ve got some suggestions for your blog you might be interested in hearing. Either way, great blog and I look forward to seeing it grow over time.

Great site. A lot of helpful information here. I am sending it to several pals ans additionally sharing in delicious. And obviously, thanks to your sweat!

You have brought up a very excellent details , thanks for the post.

I used to be more than happy to search out this internet-site.I needed to thanks for your time for this wonderful learn!! I positively enjoying every little little bit of it and I have you bookmarked to take a look at new stuff you weblog post.

I will immediately clutch your rss feed as I can’t to find your e-mail subscription link or e-newsletter service. Do you’ve any? Please let me recognize so that I may just subscribe. Thanks.

Very interesting subject, thankyou for posting. “Everything in the world may be endured except continued prosperity.” by Johann von Goethe.

Simply a smiling visitant here to share the love (:, btw great design.

Some really nice stuff on this internet site, I enjoy it.

Very nice info and right to the point. I am not sure if this is in fact the best place to ask but do you guys have any ideea where to hire some professional writers? Thx 🙂

Thank you so much for providing individuals with an extraordinarily remarkable chance to check tips from this site. It really is very nice and also stuffed with a great time for me and my office fellow workers to search your blog nearly three times in a week to learn the new guides you have. Of course, I am also always astounded considering the awesome concepts served by you. Certain 2 facts in this post are completely the most impressive I’ve ever had.

Only wanna comment that you have a very nice website , I enjoy the style and design it actually stands out.

In fact no matter if someone doesn’t understand after that its up to other visitors that they will help, so

here it happens.

Would you be occupied with exchanging links?

Only a smiling visitor here to share the love (:, btw great design and style.

Very interesting details you have mentioned, thanks for putting up. “The thing always happens that you really believe in and the belief in a thing makes it happen.” by Frank Lloyd Wright.

I really like your writing style, fantastic information, thanks for putting up : D.

I have been reading out some of your stories and it’s pretty clever stuff. I will make sure to bookmark your website.

I got good info from your blog

I’ll immediately grab your rss feed as I can’t in finding your email subscription hyperlink or newsletter service. Do you’ve any? Kindly let me know so that I could subscribe. Thanks.

After study a few of the blog posts on your website now, and I truly like your way of blogging. I bookmarked it to my bookmark website list and will be checking back soon. Pls check out my web site as well and let me know what you think.

Valuable info. Lucky me I discovered your web site by chance, and I’m stunned why this coincidence didn’t took place in advance!

I bookmarked it.

Hi there, yes this article is in fact pleasant and

I have learned lot of things from it concerning blogging.

thanks.

Keep functioning ,impressive job!

I wanted to thank you for this great read!! I definitely enjoying every little bit of it I have you bookmarked to check out new stuff you post…

It’s hard to find knowledgeable individuals on this matter, but you sound like you realize what you’re talking about! Thanks

I really like your writing style, good info , appreciate it for putting up : D.

Some genuinely interesting information, well written and loosely user pleasant.

Hi there! This post couldn’t be written any better! Reading through this post reminds me of my previous room mate! He always kept talking about this. I will forward this article to him. Pretty sure he will have a good read. Thank you for sharing!

Crypto payment gateway for your business. Boost your sales, cut costs, and streamline your operations by accepting cryptocurrency payments. Experience secure, fast transactions and unlock global business opportunities

I’m impressed, I must say. Really not often do I encounter a blog that’s both educative and entertaining, and let me inform you, you will have hit the nail on the head. Your idea is outstanding; the problem is one thing that not sufficient people are talking intelligently about. I am very blissful that I stumbled across this in my search for one thing relating to this.

Fantastic site. Lots of helpful info here. I’m sending it to a few friends ans additionally sharing in delicious. And naturally, thank you for your effort!

Admiring the commitment you put into your site and detailed information you offer. It’s nice to come across a blog every once in a while that isn’t the same unwanted rehashed information. Great read! I’ve bookmarked your site and I’m adding your RSS feeds to my Google account.

Its excellent as your other posts : D, regards for putting up.

Thanks for every other informative blog. The place else may just I am getting that kind of info written in such a perfect approach? I have a undertaking that I am just now operating on, and I have been on the glance out for such information.

Enjoyed looking through this, very good stuff, regards.

Sweet web site, super layout, really clean and utilize pleasant.

I like this weblog very much so much excellent information.

As a Newbie, I am constantly browsing online for articles that can help me. Thank you

I keep listening to the reports talk about receiving free online grant applications so I have been looking around for the finest site to get one. Could you advise me please, where could i get some?

It’s appropriate time to make some plans for the future and

it’s time to be happy. I have learn this submit and if I may

I want to counsel you few interesting issues or advice.

Maybe you can write next articles regarding this article.

I wish to read more things approximately it!

I just couldn’t depart your website prior to suggesting that I actually enjoyed the standard info a person provide for your visitors? Is gonna be back often to check up on new posts

Good write-up, I am normal visitor of one’s blog, maintain up the nice operate, and It is going to be a regular visitor for a lengthy time.

I conceive this site has got some real wonderful information for everyone : D.

Good way of explaining, and pleasant piece of writing to get data regarding my presentation topic,

which i am going to present in university.

It’s an amazing article in favor of all the web visitors;

they will take benefit from it I am sure.

I like the valuable information you provide for your articles.

I’ll bookmark your blog and check once more right

here regularly. I’m fairly certain I will be informed a lot of new stuff right here!

Good luck for the next!

When I originally commented I clicked the “Notify me when new comments are added” checkbox and now each time a comment is added I get four emails with the same comment. Is there any way you can remove me from that service? Bless you!

Nice post. I used to be checking constantly this blog and I am impressed! Extremely helpful info specifically the ultimate section 🙂 I care for such information much. I was looking for this certain information for a very lengthy time. Thanks and best of luck.

very nice submit, i certainly love this web site, carry on it

Hi! I just wanted to ask if you ever have any issues with

hackers? My last blog (wordpress) was hacked and I ended up

losing months of hard work due to no data backup.

Do you have any solutions to stop hackers?

Great write-up, I am regular visitor of one’s website, maintain up the nice operate, and It is going to be a regular visitor for a lengthy time.

Neat blog! Is your theme custom made or did you download it from somewhere? A design like yours with a few simple tweeks would really make my blog jump out. Please let me know where you got your theme. Kudos

Well I sincerely enjoyed studying it. This article provided by you is very effective for good planning.

Perfectly composed subject matter, thank you for selective information. “Necessity is the mother of taking chances.” by Mark Twain.

Hey very nice web site!! Man .. Excellent .. Amazing .. I will bookmark your web site and take the feeds also…I am happy to find numerous useful information here in the post, we need develop more strategies in this regard, thanks for sharing. . . . . .

This web site is my inspiration , real superb design and style and perfect content material.

I have been reading out a few of your stories and i can claim pretty good stuff. I will make sure to bookmark your site.

Excellent post. I was checking constantly this

blog and I am impressed! Extremely helpful

information specially the last part 🙂 I care for such info a lot.

I was seeking this certain info for a very long time.

Thank you and best of luck.

Perfect work you have done, this website is really cool with fantastic info .

Hi there, I enjoy reading all of your article post. I like to write

a little comment to support you.

Way cool, some valid points! I appreciate you making this article available, the rest of the site is also high quality. Have a fun.

Great amazing issues here. I?¦m very glad to see your post. Thanks a lot and i am having a look ahead to touch you. Will you kindly drop me a mail?

I love your blog.. very nice colors & theme. Did you make this website yourself or did you hire someone to do it for you? Plz reply as I’m looking to create my own blog and would like to know where u got this from. kudos

It’s hard to find knowledgeable people on this topic, but you sound like you know what you’re talking about! Thanks

Just what I was looking for, thanks for posting.

Very interesting details you have observed, appreciate it for posting. “Never call an accountant a credit to his profession a good accountant is a debit to his profession.” by Charles J. C. Lyall.

The Natural Mounjaro Recipe is more than just a diet—it’s a sustainable and natural approach to weight management and overall health.

Hi, I think your site might be having browser compatibility issues. When I look at your website in Safari, it looks fine but when opening in Internet Explorer, it has some overlapping. I just wanted to give you a quick heads up! Other then that, fantastic blog!

Thank you for another wonderful post. Where else could anyone get that type of information in such a perfect way of writing? I’ve a presentation next week, and I’m on the look for such information.

Mitolyn is a cutting-edge natural dietary supplement designed to support effective weight loss and improve overall wellness.

Quality content is the secret to be a focus for the viewers to pay a quick visit the web site, that’s what this

web site is providing.

It’s hard to find knowledgeable people on this topic, but you sound like you know what you’re talking about! Thanks

You mentioned this superbly!

you will have an important blog right here! would you wish to make some invite posts on my blog?

Hey there! I could have sworn I’ve been to this blog before but after reading through some of the post I realized it’s new to me. Anyways, I’m definitely glad I found it and I’ll be book-marking and checking back frequently!

Hi there! I could have sworn I’ve been to this website before but after browsing through some of the post I realized it’s new to me.

Nonetheless, I’m definitely delighted I found it and I’ll be bookmarking

and checking back frequently!

Greetings! I know this is kind of off topic but I was wondering if you knew where I could get a captcha plugin for my comment form? I’m using the same blog platform as yours and I’m having difficulty finding one? Thanks a lot!

I like what you guys are up also. Such smart work and reporting! Carry on the superb works guys I have incorporated you guys to my blogroll. I think it’ll improve the value of my site 🙂

It¦s actually a cool and helpful piece of info. I¦m happy that you shared this useful info with us. Please stay us up to date like this. Thanks for sharing.

I always was concerned in this topic and still am, thankyou for posting.

Thankyou for this post, I am a big big fan of this internet site would like to keep updated.

I just could not depart your site prior to suggesting that I extremely enjoyed the standard info a person provide for your visitors? Is gonna be back often in order to check up on new posts

fantastic issues altogether, you simply received a logo new reader. What could you recommend about your submit that you just made a few days ago? Any sure?

I’m not sure why but this blog is loading incredibly slow for me. Is anyone else having this problem or is it a issue on my end? I’ll check back later on and see if the problem still exists.

I’m not sure exactly why but this website is loading very slow for me. Is anyone else having this issue or is it a problem on my end? I’ll check back later on and see if the problem still exists.

Greetings! I know this is kind of off topic but I was wondering if you knew where I could locate a captcha plugin for my comment form? I’m using the same blog platform as yours and I’m having problems finding one? Thanks a lot!

Precisely what I was looking for, thanks for putting up.

Appreciate it for all your efforts that you have put in this. very interesting info .

You completed a few fine points there. I did a search on the subject matter and found a good number of people will consent with your blog.

Greetings! I know this is kind of off topic but I was wondering if you knew where I could get a captcha plugin for my comment form? I’m using the same blog platform as yours and I’m having problems finding one? Thanks a lot!

It’s hard to find knowledgeable people on this topic, but you sound like you know what you’re talking about! Thanks

bokep inggris

When I initially commented I clicked the “Notify me when new comments are added” checkbox and now each time a comment is added I get three emails with the same comment. Is there any way you can remove people from that service? Appreciate it!

It is in reality a great and useful piece of info. I am glad that you shared this useful information with us. Please stay us up to date like this. Thank you for sharing.

so much superb information on here, : D.

I am often to blogging and i really appreciate your content. The article has really peaks my interest. I am going to bookmark your site and keep checking for new information.

I like this blog very much so much fantastic info .

Just about all of the things you say is astonishingly precise and that makes me ponder why I had not looked at this with this light before. Your article truly did switch the light on for me as far as this particular subject goes. But there is actually 1 position I am not really too comfy with and while I try to reconcile that with the core idea of your issue, let me observe just what all the rest of your subscribers have to say.Very well done.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

I am glad to be a visitor of this gross website! , regards for this rare information! .

There is clearly a lot to identify about this. I think you made certain nice points in features also.

you have a great blog here! would you like to make some invite posts on my blog?

Mitolyn is a cutting-edge natural dietary supplement designed to support effective weight loss and improve overall wellness.

I was studying some of your content on this site and I think this website is really instructive! Keep on posting.

You have noted very interesting points! ps decent website.

The Salt Trick is a natural technique that involves using specific salts, such as Blue Salt, to enhance male performance

The Salt Trick is a natural technique that involves using specific salts, such as Blue Salt, to enhance male performance

The Salt Trick is a natural technique that involves using specific salts, such as Blue Salt, to enhance male performance

all the time i used to read smaller articles or reviews that

as well clear their motive, and that is also happening with

this piece of writing which I am reading at this place.

The Salt Trick is a natural technique that involves using specific salts, such as Blue Salt, to enhance male performance

The Salt Trick is a natural technique that involves using specific salts, such as Blue Salt, to enhance male performance

Hi there! This post couldn’t be written any better! Reading through this post reminds me of my previous room mate! He always kept talking about this. I will forward this article to him. Pretty sure he will have a good read. Thank you for sharing!

you’re in reality a good webmaster. The website loading pace is incredible. It seems that you’re doing any distinctive trick. Moreover, The contents are masterwork. you’ve performed a wonderful activity in this matter!

Really enjoyed this blog post, can I set it up so I get an alert email when you make a fresh article?

Thanks a lot for sharing this with all of us you actually know what you’re talking about! Bookmarked. Please also visit my site =). We could have a link exchange arrangement between us!

It’s actually a nice and useful piece of info. I’m glad that you shared this helpful info with us. Please keep us up to date like this. Thanks for sharing.

Hi! This post couldn’t be written any better! Reading through

this post reminds me of my old room mate! He always kept chatting about this.

I will forward this article to him. Fairly certain he

will have a good read. Many thanks for sharing!

You Get Over 22,500 PPV & Premium Channels Instantly. You Get Over 165,000 Movies & Series. Our IPTV Service is Always Up 99,99 of the Time. You Get 100 Satisfaction Guarantee. You Get the Best Price on the Market Guaranteed. You Get the Best 24/7 Customer Service.

Magnificent goods from you, man. I’ve understand your stuff previous to and you are just

extremely magnificent. I actually like what you’ve acquired here,

really like what you’re saying and the way in which you say it.

You make it entertaining and you still care for to keep it wise.

I cant wait to read much more from you. This is actually a wonderful website.

Great post. I used to be checking continuously this weblog and I’m inspired!

Very helpful information particularly the closing phase 🙂 I

deal with such info a lot. I was seeking this certain info

for a very long time. Thank you and best of luck.

Thanks for sharing. I read many of your blog posts, cool, your blog is very good.

When I initially commented I clicked the “Notify me when new comments are added” checkbox and now each time a comment is added I get four emails with the same comment. Is there any way you can remove people from that service? Thanks a lot!

I like this website its a master peace ! Glad I observed this on google .

I am not sure where you are getting your information, but great topic. I needs to spend some time learning more or understanding more. Thanks for excellent info I was looking for this info for my mission.

Appreciating the persistence you put into your blog and detailed information you offer. It’s nice to come across a blog every once in a while that isn’t the same old rehashed material. Wonderful read! I’ve bookmarked your site and I’m adding your RSS feeds to my Google account.

Your style is really unique in comparison to other folks I have read stuff from.

Thanks for posting when you’ve got the opportunity, Guess I will just bookmark this

blog.

After examine a few of the blog posts on your web site now, and I really like your way of blogging. I bookmarked it to my bookmark web site listing and might be checking back soon. Pls try my website online as effectively and let me know what you think.

Loving the information on this site, you have done outstanding job on the articles.

Fantastic site. A lot of helpful information here. I’m sending it to several pals ans also sharing in delicious. And certainly, thanks on your sweat!

Well I sincerely enjoyed reading it. This information provided by you is very effective for good planning.

Sweet site, super design, real clean and apply pleasant.

It’s actually a nice and helpful piece of information. I am satisfied that you simply shared this useful info with us. Please keep us informed like this. Thank you for sharing.

I like this website so much, bookmarked. “Respect for the fragility and importance of an individual life is still the mark of an educated man.” by Norman Cousins.

Good stuff, Thanks.

PrimeBiome is a dietary supplement designed to support gut health by promoting a balanced microbiome, enhancing digestion, and boosting overall well-being.

Fascinating blog! Is your theme custom made or did you download it from somewhere? A theme like yours with a few simple tweeks would really make my blog jump out. Please let me know where you got your theme. Bless you

Very interesting information!Perfect just what I was looking for!

Mitolyn is a cutting-edge natural dietary supplement designed to support effective weight loss and improve overall wellness.

Hey there! I know this is kind of off topic but I was wondering which blog platform are you using for this site? I’m getting sick and tired of WordPress because I’ve had issues with hackers and I’m looking at options for another platform. I would be awesome if you could point me in the direction of a good platform.

The Natural Mounjaro Recipe is more than just a diet—it’s a sustainable and natural approach to weight management and overall health.

Good write-up, I am normal visitor of one’s blog, maintain up the nice operate, and It is going to be a regular visitor for a lengthy time.

At this time it appears like Movable Type is the best blogging platform available right now. (from what I’ve read) Is that what you are using on your blog?

Usually I don’t read post on blogs, but I would like to say that this write-up very forced me to try and do it! Your writing style has been amazed me. Thanks, very nice article.

Admiring the commitment you put into your blog and in depth information you provide. It’s nice to come across a blog every once in a while that isn’t the same outdated rehashed information. Excellent read! I’ve bookmarked your site and I’m including your RSS feeds to my Google account.

I think this website contains very superb indited written content blog posts.

Great article and right to the point. I am not sure if this is truly the best place to ask but do you people have any ideea where to employ some professional writers? Thanks 🙂

Only a smiling visitor here to share the love (:, btw outstanding design and style.

It’s in reality a nice and useful piece of info. I am glad that you shared this useful info with us. Please keep us up to date like this. Thank you for sharing.

I like what you guys are up too. Such smart work and reporting! Carry on the excellent works guys I?¦ve incorporated you guys to my blogroll. I think it’ll improve the value of my website 🙂

I blog quite often and I truly thank you for your information. This article

has really peaked my interest. I am going to take a note of your website and keep checking for new details about once per week.

I opted in for your RSS feed as well.

This really answered my downside, thank you!

Keep up the great work, I read few blog posts on this internet site and I believe that your web site is very interesting and contains circles of superb information.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Admiring the hard work you put into your blog and in depth information you offer. It’s good to come across a blog every once in a while that isn’t the same outdated rehashed material. Excellent read! I’ve bookmarked your site and I’m adding your RSS feeds to my Google account.

Pretty! This was an incredibly wonderful post. Thanks for

providing this info.

You completed a few fine points there. I did a search on the theme and found nearly all folks will agree with your blog.

It’s in point of fact a great and useful piece of information. I am glad that

you just shared this helpful information with us. Please stay

us up to date like this. Thank you for sharing.

Great post. I was checking constantly this blog and I’m impressed!

Extremely useful information specifically the last part 🙂 I

care for such information much. I was seeking this certain info for

a long time. Thank you and best of luck.

Hey there, I think your website might be having browser compatibility issues.

When I look at your website in Firefox, it looks fine but when opening in Internet

Explorer, it has some overlapping. I just wanted to give you a

quick heads up! Other then that, amazing blog!

WONDERFUL Post.thanks for share..extra wait .. …

Good info. Lucky me I reach on your website by accident, I bookmarked it.

I like the helpful info you supply on your articles. I will bookmark your weblog and check once more here frequently. I’m slightly certain I’ll learn many new stuff proper right here! Good luck for the following!

Have you ever considered about including a little bit more than just your articles? I mean, what you say is valuable and everything. Nevertheless think about if you added some great images or videos to give your posts more, “pop”! Your content is excellent but with pics and video clips, this site could certainly be one of the best in its niche. Excellent blog!

I’m truly enjoying the design and layout of your blog. It’s a very easy on the eyes which makes it much more pleasant for me to come here and visit more often. Did you hire out a designer to create your theme? Great work!

It¦s really a cool and helpful piece of information. I¦m glad that you shared this useful info with us. Please keep us up to date like this. Thanks for sharing.

I¦ll immediately clutch your rss as I can’t in finding your email subscription hyperlink or e-newsletter service. Do you have any? Kindly let me realize in order that I may just subscribe. Thanks.

Hi, Neat post. There is a problem along with your web site in internet explorer, might check this… IE nonetheless is the marketplace leader and a large portion of folks will miss your wonderful writing due to this problem.

I’m really enjoying the design and layout of your site. It’s a very easy on the eyes which makes it much more enjoyable for me to come here and visit more often. Did you hire out a developer to create your theme? Great work!

Your article helped me a lot, is there any more related content? Thanks!

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

I love looking through an article that will

make people think. Also, thank you for allowing for me to comment!

Some genuinely wondrous work on behalf of the owner of this site, absolutely great content material.

Some truly wonderful articles on this website , thanks for contribution.

I do believe all the concepts you’ve offered on your post.

They are really convincing and can certainly work. Still, the posts are too brief for beginners.

May just you please lengthen them a little from subsequent time?

Thank you for the post.

great post.Ne’er knew this, appreciate it for letting me know.

Hey there, You’ve done an incredible job. I will definitely digg it

and personally suggest to my friends. I’m confident they will

be benefited from this website.

It’s really a great and helpful piece of information. I am glad that you shared this useful info with us. Please keep us informed like this. Thank you for sharing.

Outstanding post, you have pointed out some good details , I too believe this s a very wonderful website.

Helpful posts Regards!

Thanks a bunch for sharing this with all of us you really know what you are talking about! Bookmarked. Kindly also visit my site =). We could have a link exchange agreement between us!

After all, what a great site and informative posts, I will upload inbound link – bookmark this web site? Regards, Reader.

Some really select content on this web site, saved to my bookmarks.

It’s the best time to make some plans for the long run and it is time to be happy. I have learn this submit and if I may I desire to counsel you some fascinating things or tips. Perhaps you could write next articles relating to this article. I wish to read more things approximately it!

Thanks a lot. Excellent stuff.

I will immediately clutch your rss as I can’t in finding your email subscription link or newsletter service. Do you’ve any? Please allow me recognize in order that I may just subscribe. Thanks.

Good day! Do you know if they make any plugins to help with Search Engine Optimization? I’m trying to get my blog to rank for some targeted keywords but I’m not seeing very good results. If you know of any please share. Many thanks!

Hi, I check your blogs regularly. Your story-telling style is awesome, keep up the good work!

I do accept as true with all the ideas you’ve offered for your post. They’re very convincing and will certainly work. Nonetheless, the posts are very quick for beginners. Could you please extend them a bit from subsequent time? Thanks for the post.

Woah! I’m really loving the template/theme of this blog. It’s simple, yet effective. A lot of times it’s very difficult to get that “perfect balance” between superb usability and appearance. I must say you’ve done a excellent job with this. Also, the blog loads extremely fast for me on Internet explorer. Outstanding Blog!

Generally I don’t read post on blogs, but I wish to say that this write-up very forced me to try and do it! Your writing taste has been amazed me. Thank you, very great article.

Hiya very cool site!! Man .. Excellent .. Wonderful .. I will bookmark your blog and take the feeds additionally…I’m happy to find a lot of useful information right here within the put up, we want work out more techniques on this regard, thank you for sharing.

I like the efforts you have put in this, appreciate it for all the great articles.

Truly a good deal of wonderful data.

Skip SEO myths. Get real SeoFlox.com.,Real 3-7 week results for – visit ExLinko.com.,iTxoft.com is thrilled

to accelerate your plans

Incredible a good deal of very good info.

Every weekend i used to pay a quick visit this web

page, as i want enjoyment, since this this website conations actually nice

funny information too.

Keep on working, great job!

Everyone loves it when people get together

and share ideas. Great site, continue the good work!

What’s up, yeah this post is really fastidious

and I have learned lot of things from it on the topic of blogging.

thanks.

It’s hard to come by well-informed people about this subject, but you seem like you know what you’re talking about!

Thanks

Yay google is my queen aided me to find this great web site! .

fantastic put up, very informative. I wonder

why the other specialists of this sector

don’t understand this. You must proceed your writing.

I am sure, you have a great readers’ base already!

Hmm is anyone else encountering problems with the images on this blog loading?

I’m trying to determine if its a problem on my end or if it’s the blog.

Any feed-back would be greatly appreciated.

I used to be very pleased to search out this net-site.I wanted to thanks for your time for this glorious read!! I undoubtedly having fun with each little little bit of it and I’ve you bookmarked to check out new stuff you blog post.

Hmm is anyone else encountering problems with the images on this blog loading?

I’m trying to figure out if its a problem on my end or

if it’s the blog. Any feed-back would be greatly appreciated.

I wanted to thank you for this great read!! I definitely enjoying every little bit of it I have you bookmarked to check out new stuff you post…

Regards, I enjoy it!

Hi! I know this is kind of off topic but I was wondering if you knew where I could locate a captcha plugin for my comment form?

I’m using the same blog platform as yours

and I’m having trouble finding one? Thanks a lot!

Link exchange is nothing else but it is only placing the other person’s webpage link on your page at appropriate place and other person will also do similar in favor of you.

It’s hard to find knowledgeable people on this topic, but you sound like you know what you’re talking about! Thanks

Everyone loves what you guys are usually up too. This sort of clever work and coverage! Keep up the awesome works guys I’ve included you guys to blogroll.

Glad to be one of many visitors on this amazing internet site : D.

Your article helped me a lot, is there any more related content? Thanks!

I went over this website and I believe you have a lot of good info, saved to favorites (:.

I like the efforts you have put in this, thanks for all the great posts.

I’m not sure why but this website is loading extremely slow for me.

Is anyone else having this problem or is it a issue on my

end? I’ll check back later on and see if the problem

still exists.

WONDERFUL Post.thanks for share..more wait .. …

Hey! This post couldn’t be written any better! Reading this post reminds me of my previous room mate!

He always kept talking about this. I will forward this

article to him. Pretty sure he will have a good read.

Thank you for sharing!

I am glad to be a visitant of this arrant weblog! , regards for this rare info ! .

Awsome site! I am loving it!! Will be back later to read some more. I am taking your feeds also.

You really make it seem so easy along with your presentation but I in finding this topic to be really one thing which I feel I’d by no means understand. It seems too complicated and extremely vast for me. I’m taking a look forward on your subsequent post, I’ll attempt to get the cling of it!

І seriously love your site.. Εxcellent colors & themе.

Did you make this site yourself? Please reply bаck as I’m planning to cгeate my own personal website and would

like tⲟ learn where you got this from or just what the

theme is called. Thanks!

It is actually a nice and helpful piece of info. I am satisfied that you shared this helpful information with us. Please stay us informed like this. Thank you for sharing.

Time is often called the soul of motion, the great measure of change, but what if it is merely an illusion? What if we are not moving forward but simply circling the same points, like the smoke from a burning fire, curling back onto itself, repeating patterns we fail to recognize? Maybe the past and future are just two sides of the same moment, and all we ever have is now.

This information is invaluable. When can I find out more?

You made some good points there. I did a search on the topic and found a good number of folks will have the same opinion with your blog.

At this time it looks like Movable Type is the preferred blogging platform out there right now. (from what I’ve read) Is that what you’re using on your blog?

I like what you guys are up too. Such smart work and reporting! Keep up the superb works guys I have incorporated you guys to my blogroll. I think it’ll improve the value of my web site :).

You are my intake, I own few blogs and infrequently run out from to post : (.

I?¦ll immediately grasp your rss feed as I can’t in finding your email subscription link or e-newsletter service. Do you have any? Please let me recognise in order that I may subscribe. Thanks.

I am actually glad to glance at this website posts which includes lots of

valuable information, thanks for providing such information.

آفرین مطلب خوبی بود

I read this paragraph completely on the topic of the

resemblance of newest and previous technologies,

it’s remarkable article.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.

Thank you for another informative blog. The place else could

I am getting that type of info written in such a

perfect way? I have a project that I am just now working on,

and I’ve been on the glance out for such info.

I read this article completely about the comparison of latest and

previous technologies, it’s amazing article.

These are really impressive ideas in on the topic of blogging.

You have touched some good points here. Any way keep up wrinting.

It’s in reality a nice and helpful piece of information.

I am happy that you shared this helpful info with us. Please keep us up to date like this.

Thank you for sharing.

I always was interested in this topic and stock still am, appreciate it for posting.